Concrete Milling

Explore the best of our solutions

With the growing demand for highway tunnel maintenance in Italy and abroad, Laurini has developed and patented advanced solutions for the scarifying of tunnel vaults using milling machines.

These technologies enable fast and efficient removal of the superficial cement layer across the entire arch and full length of the vault before restoring the lining, significantly reducing time, costs, and disruptions to highway traffic.

Jocker: Patented Tunnel Milling Machine

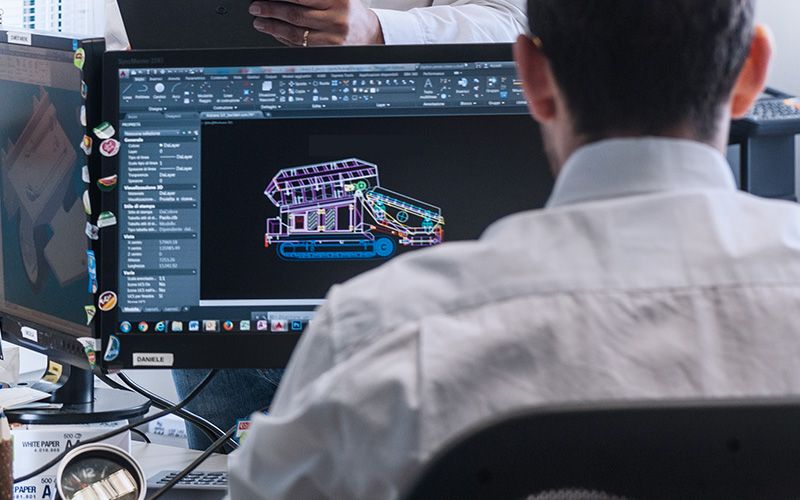

At the heart of Laurini’s offering is Jocker, a patented milling machine specifically designed for the scarifying and superficial demolition of tunnel vaults. It performs a single automated pass with a central telescopic arm system, ensuring high productivity, reduced operation times, and greater safety for the operator. Thanks to its powerful motorization (approx. 440 HP, oil flow 400 l/min, operating radius between 4.2 and 6.6 m), hydraulically stabilized base, and remote control capability, Jocker offers precision, ease of use even for less experienced operators, and transportability without requiring special permits.

Telescopic Milling Head for Excavators

Laurini also offers a full-section milling head mounted on a telescopic arm installed on a 360° rotating turret, ideal for milling inclined or overhead surfaces of tunnel vaults. It enables operations even in confined spaces within tunnels. This equipment, developed by Laurini, is suitable for 25–30 t excavators and can be quickly disassembled to revert to digging configuration.

The Advantages of Laurini Solutions

- Fast and precise removal of the cement layer

- Reduced intervention times and costs

- Operational versatility to work in any condition

- Strength and reliability typical of Laurini’s manufacturing

- Patented technology specifically designed for tunnel maintenance

Why Choose Laurini

By combining engineering innovation with in-depth knowledge of on-site needs, Laurini delivers solutions designed to ensure speed, safety, and precision during tunnel interventions. Each piece of equipment is engineered to deliver top performance, both as an independent machine and as an excavator-mounted application.

Learn more about our services

Discover the leading companies

that have chosen to rely on us